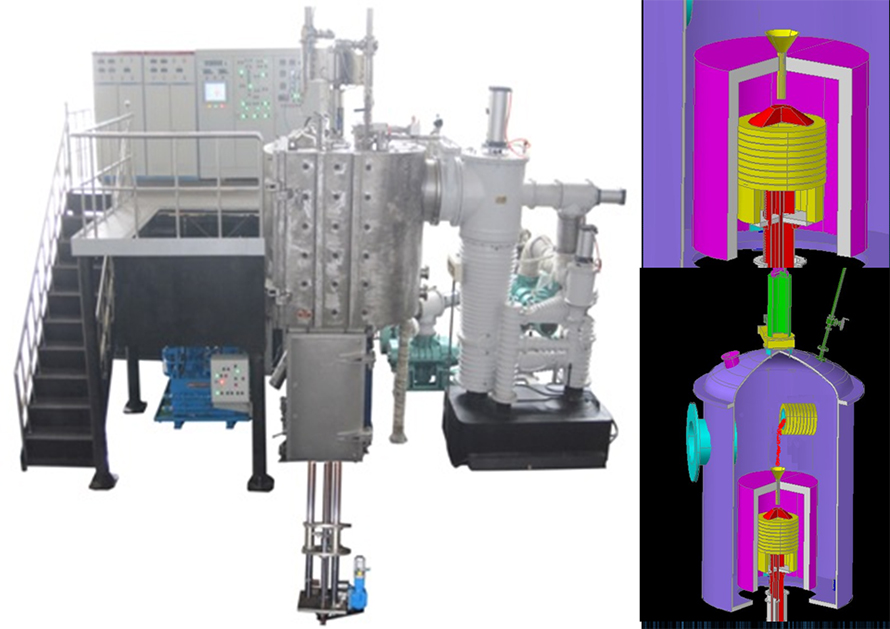

Vacuum induction directional solidifying furnace GVIM-I0D

Brief:

Vacuum induction directional induction furnace consisting of melting & holding chamber, charging & temp. measuring chamber and casting chamber is used in production of casted parts with features of uniform columnar crystal structure, manocrystal organization and resistance to high temperature, creep and thermal fatigue which are made from raw alloys including iron-based alloys, nickel-based alloys, high temperature alloys and nonferrous metal induction melting under vacuum environment or inert gas atmosphere with thermal gradient formation of special designed heating & holding system and water cooling crystallizer and then solidifying with mold up/down unit driven by servo motor.

Application:Manocrystal casted parts, turbine engine blades, gas turbine blades.

Features:Vacuum melting and casting, two zone heating & holding, water cooling crystallizing, industrial computer control, optimal product homogeneity.

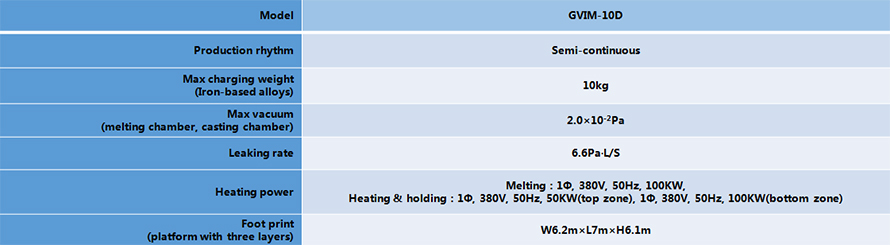

Parameters: